If you are embarking on a painting project in Fair Lawn, NJ and are uncertain about the appropriate roller cover to utilize, it is imperative to make an informed decision to ensure a smooth and uniform finish on various surfaces.

The discussion encompasses an examination of the diverse types of roller covers available, which include polyester, nylon, microfiber, foam, lambswool, and blended covers. Understanding the significance of the nap and material composition of a roller cover is crucial, along with acquiring insights on the proper care and cleaning techniques for maintaining roller covers.

By looking into the specifics of how different roller covers can be utilized for varying surfaces, one can enhance their proficiency in achieving professional outcomes in painting projects.

How to Choose the Right Roller Cover for Your Project

Selecting the appropriate roller cover for your painting endeavor is imperative for attaining a polished and professional outcome. This necessitates a comprehension of the various roller cover varieties accessible, their constituent materials, the texture of the surface under consideration, and the particular painting methodologies intended for deployment.

Factors such as surface preparation and compatibility are equally paramount considerations in the decision-making process, guaranteeing optimal paint adhesion and a durable final product.

What Types of Surfaces Can You Use a Roller Cover On?

Roller covers present a versatile solution for a range of surfaces, each necessitating specific considerations to achieve optimal paint application and finish.

The choice of roller cover must align with the surface texture to ensure effective paint application. For instance, smooth surfaces like walls and ceilings are best paired with a short nap roller cover to facilitate even coverage. On the other hand, textured surfaces such as stucco or brick may benefit from a longer nap roller cover to access crevices and guarantee thorough paint application.

When dealing with furniture, the selection of a roller cover is equally critical due to the diverse materials and finishes involved. The surface quality and smoothness are pivotal factors in determining the appropriate roller cover. A rough surface would necessitate a thicker roller cover to address imperfections, while a smoother surface would demand a finer roller cover to achieve a flawless finish.

What is the Nap of a Roller Cover?

The nap of a roller cover denotes the length of the fibers on the roller, directly impacting the texture and quality of the paint application.

Selecting the appropriate nap length is paramount for achieving desired outcomes in painting endeavors. A lengthier nap, such as 3/4-inch or 1-inch, proves suitable for uneven surfaces like textured walls or ceilings as it enables the paint to penetrate into crevices, resulting in a thicker coating. Conversely, shorter naps, like 3/8-inch or 1/2-inch, are better suited for smoother surfaces such as cabinets or doors, yielding a sleeker finish with reduced texture. Understanding the correlation between nap length and surface texture enables painters to make well-informed choices when choosing the suitable roller cover for their specific painting requirements.

What is the Material of a Roller Cover?

The selection of the roller cover material plays a critical role in determining its performance and suitability for various paint types and surface textures. Roller covers are typically manufactured using materials such as polyester, nylon, microfiber, foam, and lambswool.

- Polyester roller covers are known for their durability and compatibility with latex paints, allowing for a smooth application on walls and ceilings.

- Nylon roller covers offer exceptional durability and are well-suited for rough surfaces like concrete.

- Microfiber roller covers deliver excellent coverage and are particularly effective for achieving smooth finishes on walls and trim.

- Foam roller covers are recommended for glossy surfaces and doors.

- Lambswool roller covers are specifically designed for oil-based paints and textured surfaces, owing to their superior paint absorption and release properties.

What Size Roller Cover Should You Use?

Choosing the appropriate size roller cover is integral to ensuring effectiveness and attaining the desired paint coverage across a variety of surfaces.

Roller covers are available in a range of sizes, typically spanning from 3 inches to 18 inches, with each size tailored to a distinct function. For smaller projects or intricate tasks, a narrower roller cover measuring approximately 3-4 inches would be more suitable as it allows for enhanced precision and control. Conversely, broader roller covers, such as those exceeding 9 inches, are optimal for swiftly and efficiently covering larger surface areas.

When selecting the suitable roller cover size, it is imperative to consider the dimensions of the surface being painted and the desired finish. Furthermore, varying textures like smooth walls or textured ceilings may necessitate specific roller cover sizes to achieve optimal outcomes.

Types of Roller Covers

A comprehensive comprehension of the diverse range of roller covers on the market is essential in order to meticulously select the most suitable tool for painting endeavors. Every variety of roller cover possesses distinctive characteristics and advantages that are tailored to accommodate varying painting requirements and surface textures.

1. Polyester Roller Covers

Polyester roller covers are widely favored for their robustness and capacity to retain a substantial quantity of paint, rendering them particularly well-suited for extensive painting undertakings.

These roller covers are esteemed for their seamless application and uniform distribution, culminating in a polished final appearance. They are adept at adhering to various surfaces, encompassing walls, ceilings, and even textured surfaces. Moreover, polyester roller covers exhibit compatibility with a diverse array of paints, ranging from latex to oil-based varieties, thereby endowing them with versatility to cater to an assortment of painting requirements.

Whether the task at hand involves interior wall painting, exterior siding projects, or furniture refinishing endeavors, polyester roller covers deliver a uniform and efficient painting experience.

2. Nylon Roller Covers

Nylon roller covers are esteemed for their capacity to provide a smooth application and their resistance to shedding, rendering them highly suitable for achieving refined finishes.

These roller covers prove particularly advantageous when applied to surfaces necessitating a flawless coat, such as smooth walls, trim work, and cabinets. The composition of nylon fibers facilitates an even gliding of paint, resulting in a professional finish with minimal exertion.

Whether utilizing latex or oil-based paints, nylon roller covers showcase versatility and compatibility with an array of painting techniques. From the painting of interior walls to the undertaking of intricate endeavors like furniture refinishing, nylon roller covers consistently deliver high performance and excellent coverage.

Consequently, these roller covers are deemed an critical asset for DIY enthusiasts and industry professionals alike.

3. Microfiber Roller Covers

Microfiber roller covers have been specifically engineered to deliver a uniform and sleek finish, particularly suited for application on smooth and semi-smooth surfaces.

- Renowned for their exceptional paint absorption and controlled release capabilities, these roller covers ensure a consistent application process while minimizing streaks or roller marks.

- Their lint-free composition renders them ideal for achieving a professional-grade outcome, preventing any fibers from becoming embedded in the paint.

Whether the task at hand involves painting walls, ceilings, cabinets, or furniture, microfiber roller covers offer versatility and superior coverage. When striving for flawless, streak-free results, the inclusion of these roller covers in your painting toolkit is critical.

4. Foam Roller Covers

Foam roller covers are recommended for the application of thin, even layers of paint on smooth surfaces to achieve a flawless finish. Their distinctive foam texture enables seamless and consistent paint application while avoiding streaks or brush marks. These roller covers are particularly suitable for projects involving the painting of walls, cabinets, doors, and trim, where a sleek and uniform finish is essential. They are highly compatible with latex and acrylic paints, offering superior coverage and reducing splatter. When used on smooth surfaces such as drywall or wood paneling, foam roller covers are effective in achieving a professional aesthetic with minimal exertion.

5. Lambswool Roller Covers

Lambswool roller covers are renowned for their outstanding paint-holding capacity and ability to facilitate smooth application, rendering them particularly well-suited for extensive and uneven surfaces. The inherent qualities of lambswool roller covers engender a soft and uniform finish, imparting a professional aesthetic to painting endeavors.

These roller covers exhibit exceptional performance on textured walls or surfaces necessitating enhanced coverage. Their superior paint-holding capacity translates to reduced return trips to the paint tray, thereby streamlining the painting process.

In scenarios where surfaces like stucco, brick, or other irregular surfaces are being addressed, lambswool roller covers provide uniform coverage and reduce splatter. Especially for undertakings involving interior walls or ceilings where a polished finish is sought, the selection of lambswool roller covers ensures a seamless application process yielding a superior end result.

6. Blended Roller Covers

Blended roller covers are designed by combining different materials to achieve a balance between durability, paint-holding capacity, and the ability to provide a smooth application. These versatile roller covers are well-suited for a diverse range of painting projects, encompassing anything from painting smooth walls to textured surfaces such as stucco or brick. The incorporation of various materials, typically a blend of polyester and nylon, facilitates excellent paint pickup and release, ultimately resulting in a uniform finish.

Whether the task at hand involves painting a large interior wall or details requiring intricate trim work, blended roller covers ensure consistent coverage while minimizing splatter. Their compatibility with both water-based and oil-based paints renders them a preferred choice for professional painters and do-it-yourself enthusiasts due to their versatility and performance capabilities.

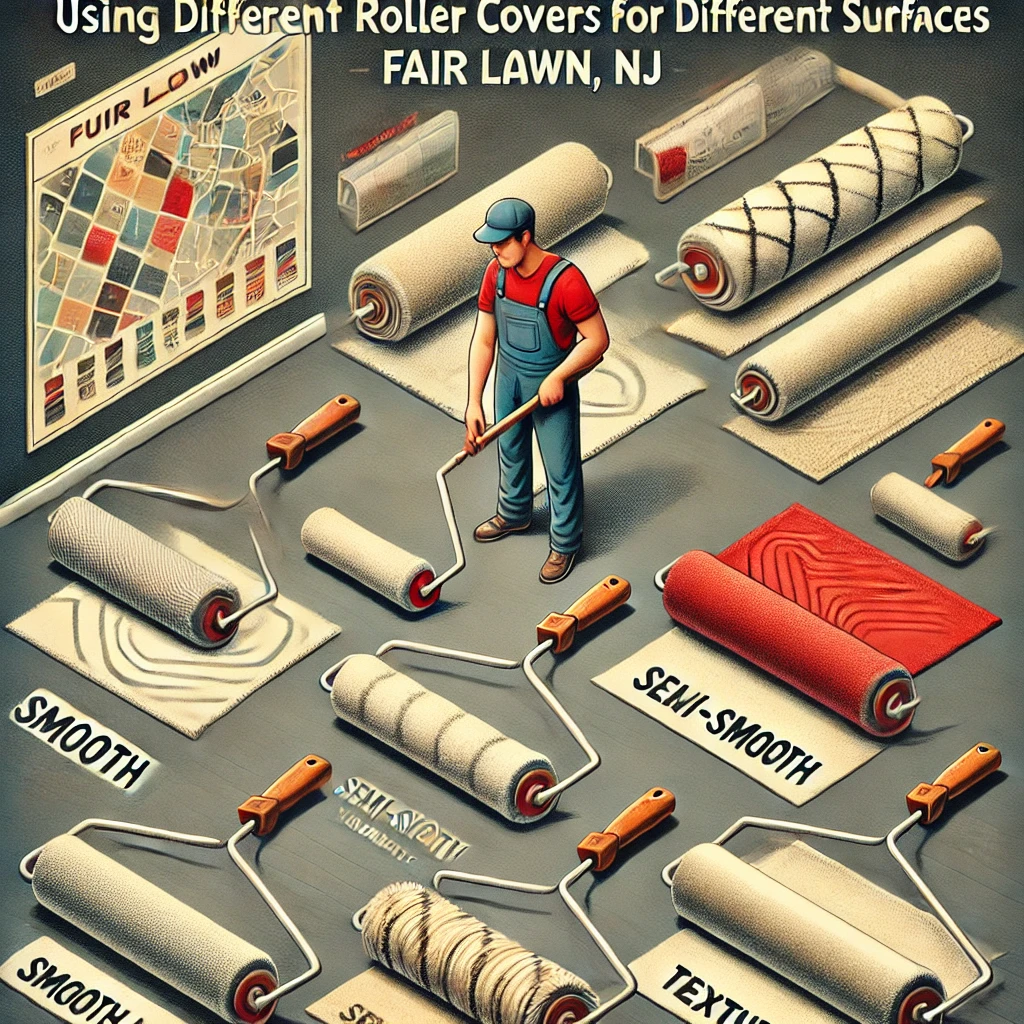

How to Use Different Roller Covers for Different Surfaces

Utilizing the appropriate roller cover for various surfaces is imperative in attaining optimal paint application and surface finish. Every surface type, whether smooth, semi-smooth, rough, or textured, necessitates a specific roller cover to guarantee the best possible outcomes.

1. Smooth Surfaces

To achieve a flawless paint application and high-quality surface finish on smooth surfaces, it is imperative to select a roller cover with a short nap length. Ideally, a roller cover with a nap length ranging from 3/16 to 1/4 inch is recommended for surfaces such as walls, cabinets, doors, and trim that require a smooth finish. When utilizing a short-nap roller cover for paint application, it is advised to use a high-quality paint that possesses good flow properties and self-leveling characteristics to attain a professional outcome.

To ensure a smooth and uniform finish, it is essential to load the roller evenly and apply the paint consistently without exerting excessive pressure. For ultra-smooth surfaces like glossy finishes or metal surfaces, it may be beneficial to consider using microfiber or foam roller covers. These specialized roller covers can enhance the application process and result in a more refined finish on surfaces that demand a higher level of smoothness.

2. Semi-Smooth Surfaces

For the effective coverage of semi-smooth surfaces while achieving a smooth finish, it is essential to utilize a roller cover with a medium nap.

When tasked with painting semi-smooth surfaces, selecting the appropriate roller cover nap is of paramount importance to ensuring optimal coverage and a flawless outcome. Opting for a medium nap roller cover facilitates the penetration into the slight irregularities of the surface, thereby enabling the paint to be distributed uniformly. To attain a uniform finish on semi-smooth surfaces, it is imperative to apply the paint in a consistent direction to prevent streaks or uneven coverage. It is advisable to utilize a high-quality roller cover composed of synthetic materials for enhanced durability and ease of cleaning. It is crucial to bear in mind that the key to achieving a professional-grade paint job on semi-smooth surfaces hinges upon the selection of the suitable roller cover and the precise application of the paint.

3. Rough Surfaces

Adequate paint coverage and the filling of the uneven texture on rough surfaces necessitate the use of a roller cover with a long nap. It is crucial to select the appropriate roller cover nap when painting rough surfaces to avoid leaving gaps and to achieve a polished finish. Ideally, opting for a roller cover with a nap size between 3/4-inch to 1-inch is recommended, as it can effectively reach into the crevices and contours of textured walls.

When painting rough surfaces, employing a technique that applies slightly heavier pressure to work the paint into the uneven areas is essential. To ensure complete coverage on rough surfaces, high-quality roller covers with a thick nap are advisable, as they can efficiently handle the textured surface.

4. Textured Surfaces

Textured surfaces necessitate the use of a roller cover with a suitable nap length capable of accommodating the variations in texture and facilitating uniform paint application.

When faced with the task of selecting a roller cover for textured surfaces, one must take into account the depth of the texture and carefully choose a nap length that possesses the ability to effectively reach into the crevices. For rough textures such as popcorn ceilings or textured walls, it is advisable to opt for a longer nap cover, typically around 3/4 inches or more, to guarantee adequate coverage. Thicker nap covers are most suitable for surfaces characterized by pronounced texture, while shorter naps are more appropriate for smoother textures.

To achieve a uniform finish on textured surfaces, it is recommended to employ a deliberate and measured rolling technique, ensuring that each stroke overlaps slightly to seamlessly blend the paint. The selection of a roller cover fashioned from high-quality materials is crucial in preventing shedding and promoting a smooth painting process.

Tips for Properly Caring for and Cleaning Roller Covers

It is imperative to properly care for and clean your roller covers in order to prolong their lifespan and preserve their effectiveness for forthcoming painting projects.

A crucial aspect of maintaining roller covers is ensuring thorough cleaning after each use. The process entails first removing excess paint by scraping the cover with a putty knife. Subsequently, the cover should be rinsed under warm water until the water runs clear. In cases of heavily soiled covers, a mild detergent or roller cover cleaner can be utilized to eliminate all remnants of paint. Following the cleaning process, it is advised to allow the covers to air dry completely before storing them in a cool, dry location that is shielded from direct sunlight.

Furthermore, it is recommended to routinely inspect roller covers for signs of wear and tear, as any damaged covers should be promptly replaced to prevent streaks or debris from affecting the quality of the paintwork.

Frequently Asked Questions

What are the benefits of using different roller covers for different surfaces in Fair Lawn, NJ?

Using the right roller cover for a specific surface can improve the overall finish, reduce paint splatter, and make the painting process more efficient.

Can I use the same roller cover for all surfaces in Fair Lawn, NJ?

No, it is not recommended to use the same roller cover for all surfaces. Different surfaces require different types of roller covers for optimal results.

What type of roller cover should I use for smooth surfaces in Fair Lawn, NJ?

For smooth surfaces, a short nap roller cover is recommended. This type of cover will provide a smooth, even finish without leaving any texture.

Which roller cover should I choose for textured surfaces in Fair Lawn, NJ?

A long nap roller cover is best for textured surfaces as it can reach into the crevices and provide even coverage.

How do I choose the right roller cover for a specific surface in Fair Lawn, NJ?

You should consider the texture and porosity of the surface when choosing a roller cover. A smooth surface will require a short nap cover, while a textured surface will need a long nap cover.

Can I reuse roller covers for different surfaces in Fair Lawn, NJ?

No, it is not recommended to reuse roller covers for different surfaces. The paint residue and texture of the surface can affect the quality of the finish on the next surface.